Lifting Station

Categories

Description

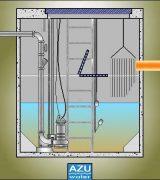

A lifting stations (or lift stations) is a tank equipped with pumps, control panels, remote monitoring equipment, level sensors or level transducer and piping. Wastewater leaving homes, buildings and businesses normally flow by natural gravity. Where it is not possible to install a gravity flow style sewer, a wet well needs to hold the wastewater. There are many kind of pumps, either submerged or connected to the wet well.

Lifting stations, also known as wet wells, are used for pumping wastewater from a lower to higher elevation, particularly where the elevation of the source is not sufficient for gravity flow or when the use of gravity conveyance will result in excessive excavation and higher construction costs.

Lifting station equipments and systems are often installed in an enclosed structure.

Centrifugal pumps are commonly used. Double pump configuration is better than single, due to alternating or emergency operation.

Single, double channel, open impeller (as vortex) and grinder pumps are used for wastewater, depending on process discharge characteristics (pre-treated or not), altitude differences, etc.

Basic types of wastewater pumps are sump, effluent, sewage and grinder.

A sump pumps is used to remove water accumulated in a collecting basin found in the basement of homes and buildings.

An effluent pump is designed to transfer the pre-treated wastewater from an onsite sewage treatment systems.

Solids-handling sewage pumps pass solids in full-form.

Grinder pump reduces the size of solids in wastewater by grinding them into a slurry and seem to be a good solution even it requires larger power instead the others.

Depending on model it can be submersible or in a dry pit with piping connected to the wet well.

There are different kind of pumps as for design, materials and functions.

Pumps and piping need associated valves (check valve, ball valves, gate valves, plug valves). Almost all the pumps installed are electric and need a power supply system as well as an equipment control.

Lift stations may have audible and visual alarms and also have remote alarms that automatically will notify to personnel the equipment failures.

It is very important to provide an odour control system and ventilation system.

The design criteria that needs to be identified for first is the total (instant) system inflow rate and pumps discharge flow.

The discharge flow can be found at the intersection of the system curve and the pump performance curve.

Pump operating point.

Pump performance is reported in the data sheets provided by manufacturers, whereas system curve is calculated for different situations. It is the sum of static head and hydraulics head loss.

A generalized equation describing the system curve of a process is:

H = Hg + Hf

where:

H is the required pump discharge pressure (total head in meters);

Hg is the static or elevation head (in meters);

Hf is the head loss (in meters).

Static heads is highest elevation opened to the atmosphere minus the system’s low point.

Head loss is friction head minor losses depending on flow rate, pipe diameter, material, valves type and shape, curves, etc.

Head loss is the pressure drop caused by friction and are the sum of major loss and minor loss.

Major loss is the pressure (energy) loss in a strength pipe with constant section and minor loss is due to fittings, bends, couplings, valves or diameter change.

Hf = sum( ji(V;D;m) Li) + sum(Vi;fi)

where

j is the head loss coefficient;

V is the medium velocity depending on flow;

D is the diameter;

m means material characteristics;

L is the pipe length;

fi is the local friction coefficient.

One of the main design target is the determination of the minimum storage net volume which the wet well needs to hold between pump starts. The minimum time between pump starts should be specified in technical sheet by manufacturer.

Also the minimum run time of the pumps must be verified according to technical sheet.

In order to evaluate the net volume, designers must considered slump volume (minimum level), working volume (between pump on and off level) and emergency storage volume (alarm level).

Plants are often equipped with a screen or grinding to remove coarse materials or with a primary treatment as septic tank for small size solutions.

Lift station operation and maintenance are handled by wastewater treatment personnel.

Lift stations may have acoustic and visual alarms as well as remote GSM alarms, that automatically notify equipment failures to personnel.

Most important European standards about lifting stations are:

- EN 12050-1 – Wastewater lifting plants for buildings and sites. Principles of construction and testing. Lifting plants for wastewater containing faecal matter;

- EN 12050-2 – Wastewater lifting plants for buildings and sites. Lifting plants for faecal-free wastewater;

- EN 12050-3 – Wastewater lifting plants for buildings and sites. Lifting plants for limited applications;

- EN 12050-4 – Wastewater lifting plants for buildings and sites. Non-return valves for faecal-free wastewater and wastewater containing faecal matter.

For lifting plants regulations required a Declaration of Performance (DoP), as provided by the EU Regulation. 305/2011.

An excessive amount of toilet paper, sanitary produce, stringy material or hard solids as plastic, rags, etc. can damage the system.

Solid materials can often plug or damage pump impellers; so periodic cleaning is required to remove the solid material from the lift station.

Pumps installation requires auto coupling system and guide rail, bases for correct maintenance and replacement operations according to EN standard regulations.

Wet well is an underground tank and it can be made by different materials, concrete, polyethylene, polypropylene, glass-reinforced plastic (GRP), according to the design requirements as the laying depth, groundwater level, all handling requirements, weight.

Products in category Lifting Station

-

Open impeller submersible pump TECNO

TECNO is a submersible electric pump for clear or slightly dirty water with open multi-vane fully submerged impeller. The particular strength of TECNO submersible electric pump, obtained with…

-

Lifting station LIFT C

LIFT C is a wastewater lifting plant for buildings and sites. It is used for houses, offices and industrial users. LIFT C pumps water from the outlet pipe to the receiving body (sewerage or water bod…